Difference Between Hot Riveting and Cold Riveting

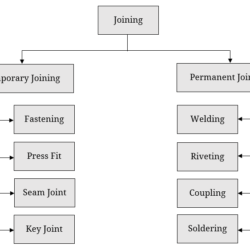

Rivet joining is one type of permanent joining process that can join two metallic components sufficiently strongly. It provides a durable, sound and reliable joint; especially the anti-loosening capability even under incessant vibration favors riveting over welding in many occasions including bridge constructions. Riveting is basically lap joining of two parts using rivets with the assistance of strap plates. Rivet is basically a small cylindrical rod usually made of soft