Feasibility of making a product from natural organic or inorganic resources depends on the advancement of science and is accelerated by the human need. However, easy, efficient, productive, economic and ergonomic conversion of raw materials to useful products as per the customers’ requirement relies on the growth of technology and assistance of management and planning. Although it is not always feasible to fulfil every requirement in a single product, in order to sustain in the competitive market, successful companies always try to incorporate functionalities as much as possible within a single product without increasing price of the product or sacrificing other necessary qualities.

It is the biggest challenge for mechanical engineers to constantly upgrade output to achieve a new feat in the globalized market. Every conversion process embraces a large number of steps and at the same time it takes assistance from other fields. Accordingly three terms—production, manufacturing and machining, have emerged, which are sometimes used interchangeably; however they are not exactly same. Let us take a look at their boundary and relationship among themselves with respect to direct consumer product fabrication.

What is production?

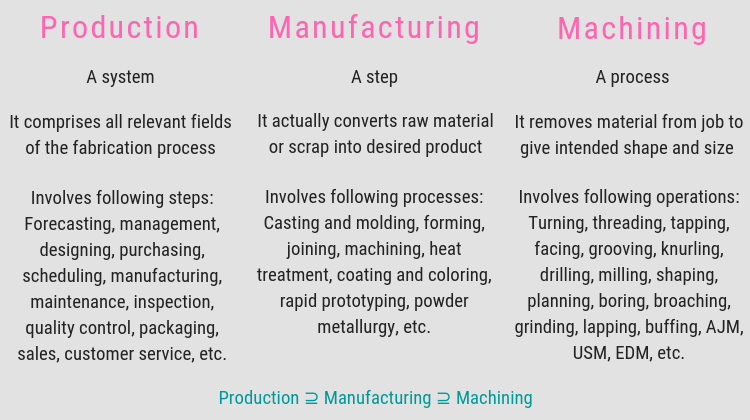

Production is the system that comprises all fields relevant to the fabrication process. It is not just the step that processes raw material to produce intended item; but it involves every associated steps. Mostly it starts with market survey where relevant information about previous similar products and new requirement are gathered directly from the customer and subsequently analysed to dig out new idea. It seeks the approval of management for finalizing the new product. However, management team also go through the views of other sectors including safety and legal aspects.

Once the idea is approved, it becomes the task of the design team to give an aesthetic look to the product considering feasibility to manufacture. The design is then converted to the actual physical product via manufacturing. Here also many other fields give direct and indirect input; for example maintenance and inspection are constantly carried out while manufacturing. The manufactured products are then required to pass through tight quality control and if accepted then come out as final product that can be sent to market for selling to the consumers after proper packaging. Once again feedback is collected directly from the customers and the same is utilized to get a new idea.

Thus it is a close loop system that encompass every single input intended for fabricating customer product. Typical fields that fall within the boundary of production are forecasting, management, planning, designing, purchasing, storing, scheduling, manufacturing, maintenance, inspection, quality control, packaging, sales, and customer relationship. Therefore, manufacturing is just one element of production set.

What is manufacturing?

Manufacturing is that step in production which actually converts raw material or scrap into desired product. It is one step; neither a system nor a process. However, this step consists of a large number of processes to efficiently and economically convert raw materials or scraps into desired products by adding sufficient value to it.

With the rapid advancement in technology, now-a-days a wide variety of manufacturing process exists to cater the need of processing different materials in several ways. Such processes include, but is not limited to, casting, forming, joining, machining, heat treatment, coating and coloring, rapid prototyping, powder metallurgy, etc. Each of them has different capability to systematically produce a particular set of features.

Therefore, manufacturing step is fulfilled by one or more of the above-mentioned processes. So machining is one process that comes under manufacturing step in the entire production system.

What is machining?

Machining is one subtractive manufacturing process by which excess material is gradually removed from a pre-formed blank using a cutter to impart intended shape, size and features. Primary purpose of machining is to improve dimensional accuracy and tolerance level by removing layer by layer material from one basic workpiece. Machining process encompasses several operations that actually perform intended task. Once again there exist wide variety of operations to fulfil actual requirement.

Broadly, machining processes can be classified as conventional process (where metallic cutter is used), abrasive process (where abrasive cutter is used) and non-traditional process (where so called cutter is not used). Turning, threading, tapering, chamfering, spinning, tapping, necking, filleting, facing, grooving, parting, knurling, drilling, milling, shaping, planning, slotting, boring, hobbing, broaching, etc. are operations that come under conventional machining process. Grinding, honing, lapping, buffing, polishing, superfinishing, etc. are considered as abrasive cutting operations. AJM, USM, WJM, EDM, ECM, LBM, PAM, IBM, etc. are non-traditional machining operations.

Therefore, it can be concluded that production is one system than indicates each and every step associated with a product fabrication. Manufacturing is one such step that actually converts raw material to desired product by adding substantial value. Such realization is made with the help of one or more machining processes. Hence turning, milling, etc. (operations) fall within machining (process), which comes under manufacturing (step) of the production (system).

Scientific comparison among production, manufacturing and machining is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Difference Between Production, Manufacturing and Machining from difference.minaprem.com.

- Principles of Engineering Manufacture by V. Chiles, S. Black, A. Lissaman and S. Martin (3rd edition, Butterworth-Heinemann).