Metal cutting or machining is one of the secondary manufacturing processes by which excess material is gradually removed by shearing from a pre-formed blank in the form of chips using a wedge shaped cutting tool in order to obtain intended form having better finish, high dimensional accuracy and close tolerance. It is one type of subtractive manufacturing process where layer by layer material is removed from a solid blank to get desired product. There exist a large number of machining processes—each having different capability and is suitable for specific purposes. Examples include straight turning, taper turning, internal turning, threading, facing, drilling, boring, reaming, tapping, planing, shaping, slotting, milling, fly cutting, hobbing, lapping, honing, grinding, etc.

For uninterrupted removal of material from workpiece, relative motion in particular direction between cutter and job is necessary. Such motions can be of two types—formative motions and auxiliary motions. Cutting motion (CM) and feed motion (FM) are formative motions; while depth of cut, relieving motion, etc. are auxiliary motions. Cutting motion imparts necessary cutting velocity, while feed motion imparts feed rate. Simultaneous action of cutting velocity and feed velocity helps removing material from the entire work surface. In some machining operations, either workpiece or cutting tool rotates; while in case of others, either workpiece or cutting tool reciprocates. Such rotation or oscillation provides intended cutting velocity and feed velocity.

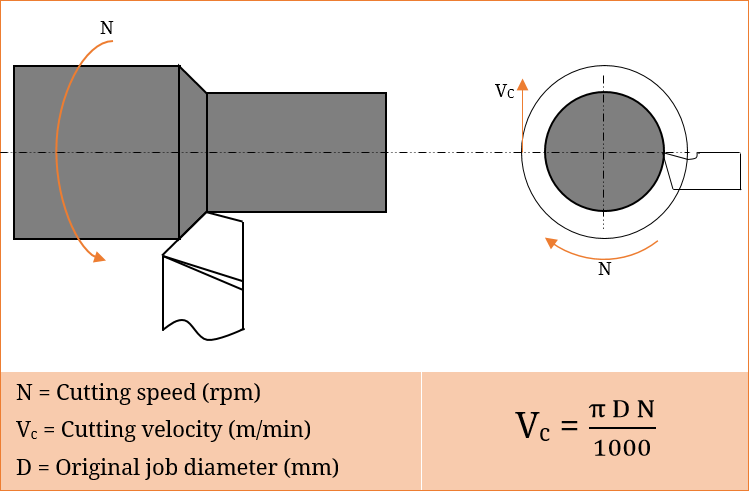

With reference to rotating type operations, there exist two different terms to indicate rotational characteristics. First one is the number of rotations completed per unit time (usually minute), which is technically termed as cutting speed and is expressed in rpm (revolutions per minute). Another alternative can be the tangential velocity of the rotating body, which gives cutting velocity and is expressed in m/min (meters per minute). It is worth mentioning that either cutter or workpiece can rotate (based on operation); correspondingly speed or velocity can be associated with cutter or workpiece (whichever is rotating). With reciprocating type machining operations, linear velocity of the workpiece or cutter (whichever is reciprocating to provide CM) is termed as cutting velocity. In such cases cutting speed does not exist due to absence of rotating body. Various differences between cutting speed and cutting velocity are given below in table format.

Table: Differences between cutting speed and cutting velocity

| Cutting Speed | Cutting Velocity |

|---|---|

| Cutting speed is the rotational speed of cutter or workpiece, as the case may be. | Cutting velocity is the tangential velocity at periphery of cutter or workpiece (whichever is rotating). |

| It is commonly expressed in revolutions per minute (rpm). | It is commonly expressed in meters per minute (m/min). |

| Speed is one scalar quality. | Velocity is vector quantity. |

| Cutting speed exists only for rotating type machining operations. | Cutting velocity is inherent to every machining operation. |

| It is not usually used for machining analysis. | Velocity is one important process parameter and it frequently used in analysis. |

Relation between cutting speed and cutting velocity: Cutting speed indicates the rotational speed of either workpiece or cutter (whichever is rotating). Tangential velocity at a point on the periphery of such rotating body is termed as cutting velocity. Thus one can be converted into another provided that diameter of rotating body is known. The following simple formula can be used for the sake of conversion in case of turning. Note that the formula is written based on the unit of each parameter as specified there.

Unit and notation: Cutting speed is commonly expressed in revolutions per minute (rpm). However, in certain cases, especially with high speed machining, speed can also be specified in revolutions per second (rps). Notation N (in capital) is used to denote speed in rpm; while n (in small) is used to denote speed in rps. Sometimes S is also used to denote speed, especially while writing CNC programme. On the other hand, cutting velocity is commonly expressed in meters per minute (m/min) and is denoted by Vc. Rarely it is expressed in meters per second (m/s).

Cutting speed is scalar but cutting velocity is vector: A scalar quantity is one that has only magnitude but no direction; while a vector quantity has magnitude along with direction. In order to fully describe the cutting speed, only magnitude with corresponding unit is sufficient. To specify cutting velocity, direction should be specified apart from magnitude and corresponding unit. However, for every machining operation, direction of cutting velocity is fixed based on the orientation of cutter and workpiece. Thus mentioning direction is not required while specifying it.

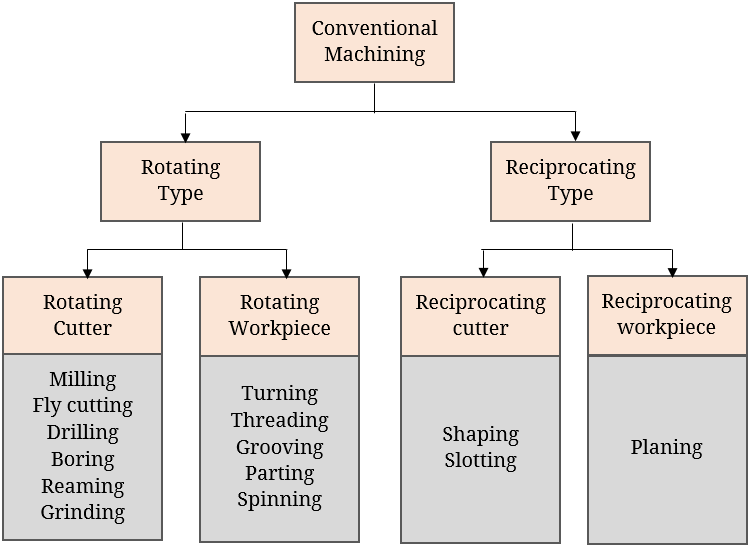

Rotating type and reciprocating type operations: Different machining operations are carried out in different ways. In some cases, either cutting tool or workpiece rotates; while in other cases, either cutting tool or workpiece reciprocates to impart cutting motion. A classification of machining operations on this ground along with typical examples is depicted below. Note that such a classification is primarily based on cutting motion (CM) and does not take care of feed motion (FM) or other auxiliary motions. Since cutting speed denotes the rotational speed, so it is relevant only in such machining operations where either cutting tool or workpiece rotates. In reciprocating type operations, cutting speed term is irrelevant. However, cutting velocity exists in all cases. With rotating type operations, the tangential velocity of cutter or workpiece on its periphery indicates cutting velocity; while in reciprocating type operations, the linear velocity of cutter or worktable indicates cutting velocity.

Usage: Machine tool mostly works on cutting speed. However, for its selection cutting velocity is first required to select judiciously and then speed is calculated using diameter of cutter or job. Cutting velocity is one of the three process parameters (other two are feed rate and depth of cut) and has great impact on machining performance. Due to its influence on a larger number of factors, it is used to analytically estimate cutting force, power consumption, machining time, cutting temperature, tool life, machinability, etc.

Scientific comparison among cutting speed and cutting velocity in machining is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Machining and Machine Tools by A. B. Chattopadhyay (1st edition, Wiley).

- Manufacturing Engineering and Technology: SI Edition by S. Kalpakjian and S. R. Schmid (7th edition, Pearson Ed Asia).