Spring is one mechanical element that can undergo significant amount of elastic deformation under the action of external loading. During its elastic deformation, spring can absorb mechanical energy and can subsequently release it in a controlled manner by regaining the original shape. It is used to introduce some amount of flexibility whenever desired in the mechanical system or structural element. Several functionalities can be obtained easily by manipulating the usage and fittings of spring. Certain common purposes that can be achieved by various types of springs include absorbing mechanical shock and vibration (for example suspension springs in vehicle and vibration dampers), applying force and controlling motion (for example cam-follower, brake and clutch), storing energy and releasing it in a controlled way (for example toys, spring-loaded watches), and also measuring force (for example weighting balance).

There are different types of spring—each one is suitable for a particular type of application. During its service life, a spring can experience axial force (tensile or compressive), torsion, bending moment, or a mixed type force. Accordingly, several types of springs are also available, which include helical spring, leaf spring, spiral spring, Belleville spring, volute spring, and disk spring. Specialized springs are also frequently used to fulfil a particular requirement. Among these, helical spring is more popular as it can be used for low-duty applications (like toys, door hinges, ball-point pens, etc.) as well as heavy-duty applications (like suspension spring of transport vehicles, railway buffer system, vibration dampers, etc.).

A helical spring consists of a fixed diameter wire bent in the form of helix. Helix angle as well as the gap between two adjacent coils of the helix can be controlled during its manufacturing. Sufficient gap between two adjacent coils of a helical spring is necessary if the spring is intended to compress under axial loading. Such helical springs, which are intended to shorten its length under the action of axial compressive loading, are called compression spring. A compression spring is sometime termed as open coiled spring as the coil of the helix is not wound tightly. On the contrary, if the helical spring is made by tightly winding the coil keeping no visible gap between two adjacent coils, then it is called close coiled spring. Such a spring cannot undergo compression; instead, they are made to experience tensile loading or torsion. This type of spring is called extension spring or tension spring. Various differences between compression spring and extension spring are given below in table format.

Table: Differences between compression spring and extension spring

| Compression Spring | Extension Spring |

|---|---|

| A compression spring is meant for shortening its length under the action of external force. | An extension spring is meant for increasing its length under the action of external force. |

| Compression spring will push the structural member to increase its length. | Extension spring will pull the structural member to reduce its length. |

| Sufficient gap must exist between two adjacent coils to allow compression. | Gap between adjacent coils is not desired as no further compression is intended. Extension springs are usually wound tightly. |

Typical applications of compression spring include:

|

Typical applications of extension spring include:

|

What are compression and extension springs? Every spring is a flexible mechanical element and should undergo large amount of elastic deflection. This deflection may be either elongation or reduction in length of the spring. Both compression and extension springs are basically helical springs (coil springs); however, they are made to serve two different purposes. In case of helical compression spring, the external force tends to compress the spring. Thus length of such spring reduces when subjected to external loading. On the other hand, extension spring undergoes increment in length when subjected to external loading.

Pulling or pushing the structural members: One of the crucial purposes of every spring is to store mechanical energy when it is elastically deformed (elongated or compressed) by external loading and subsequently release that energy by regaining original shape upon removal of external load. Under the action of external load, a compression spring will shorten its length storing energy within it. Such loaded spring will continuously push the connecting members to expand its own length to revert back to its original position by releasing stored energy. On the contrary, an extension spring will store energy when it is elongated by the action of external load. So it will continuously pull the connecting members to regain its original length by releasing stored energy.

Gap between adjacent coils: Actual length of any helical spring in unloaded condition is called free length. Length of any helical spring corresponding to full compression is called solid length and this indicates minimum possible length of any helical spring. However, solid length may go beyond elastic limit based on spring material, wire diameter, helix angle and other parameters. Sufficient gap must be provided between adjacent coils of a compression spring to facilitate compression in axial length under the action of external load. Such a spring can be compressed until adjacent coils touch teach other (that is until solid length is achieved). On the contrary, extension springs are not meant for compression and thus gap between adjacent coils are not necessary. In fact, this gap will increase when such coils are subjected to tensile loading. Thus extension springs can be wound tightly to minimize longitudinal space requirement without sacrificing spring stiffness.

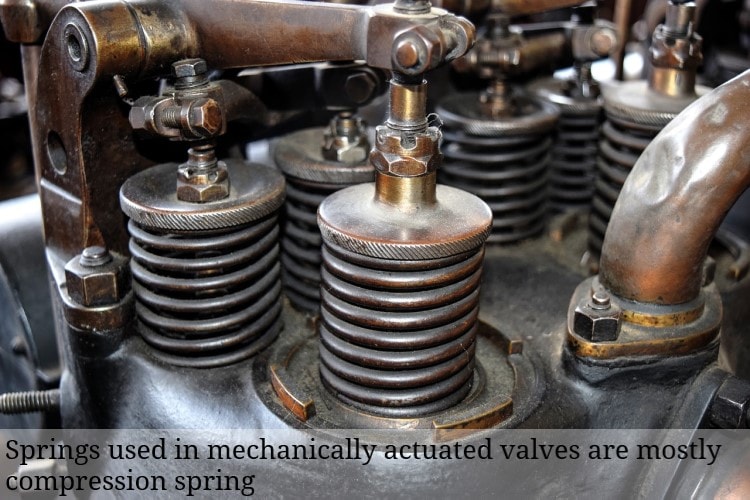

Applications of compression and extension springs: A common application of compression spring is in spring-operated ball-point pen. When the head is pressed to take out the nib, the internal spring gets compressed and energy is stored in it. This energy is released as the spring returns back to actual shape when the head is pressed again to bring in the nib. Such springs are also frequently used in mechanically controlled cam-follower mechanisms, certain valves, etc. Based on the size, a number of extension springs are used in the trampoline that provide necessary rebounding force. When someone jumps on it, the springs are extended and energy is stored in it. Springs then release this energy automatically by reducing its length to regain its original shape. This, in turn, exerts an upward force to help the person jump higher. However, spring-free trampolines, usually of smaller size, are also readily available in market. The car garage door lifting mechanism is also integrated with a pair of torsion spring or extension spring to reduce the effort required for lifting the heavy door.

Scientific comparison among compression spring and extension spring is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Design of Machine Elements by V. B. Bhandari (Fourth edition; McGraw Hill Education).

- Machine Design by R. L. Norton (Fifth edition; Pearson Education).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand; 2014).