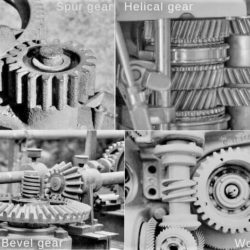

Difference Between Straight Bevel Gear and Spiral Bevel Gear

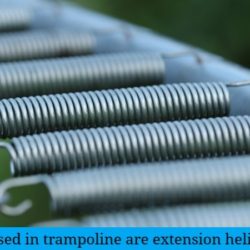

Machine can be defined as a cluster of mechanisms that can perform certain task by expanding energy. Such mechanisms are driven by mechanical power, which come in the from of rotational torque. A prime mover (such as electric motor, turbine, etc.) usually supplies mechanical power and it is then transmitted to the machine unit with the help of mechanical drives. There are four mechanical drives, namely gear drive, belt drive,