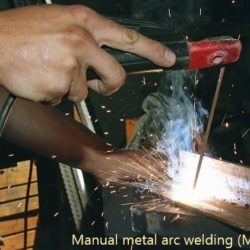

Difference Between SMAW, GMAW and GTAW Welding Processes

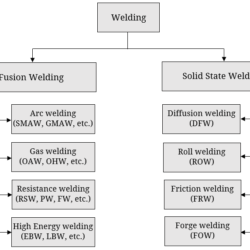

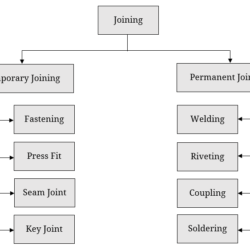

Welding is one fast and reliable joining technique that has almost replaced other permanent joining processes. It can be defined as one joining process by which two or more materials can be assembled permanently with or without the applications of heat, pressure and filler. It can be overwhelmingly used for joining not only metals but also other types of materials including plastics and ceramics. To cater the need of joining