Spring is one mechanical or structural element that can undergo significant amount of elastic deformation and thereby introduces flexibility into the system. During elastic deformation under the action of external loading, the spring absorbs mechanical energy, which is subsequently released when it regains original shape and size. Spring is used predominantly in mechanical systems and also in certain structural elements. Its diverse field of application include storing energy and releasing it in a controlled way (for example mechanical spring-loaded watches and toys), to absorb mechanical shock and vibration (for example automobile suspension springs and railway buffer springs), to control motion and apply force (for example cam-followers, vehicle brakes and clutches), and also to measure force (for example weighting balance).

There are different types of springs, which are designed to suite a particular type of application. Spring is usually designed on the basis of type of force that the spring is expected to endure throughout its service life. Several types of force that can act on a spring include axial force (tensile and compressive), torsion, bending, or a mixed type of force. Various types of springs that are commonly employed in mechanical systems are helical or coil spring, leaf spring, spiral spring, Belleville spring, and disk spring. Among these, helical spring can fulfil the requirement of diverse fields ranging from low duty (like ball-point pen) to heavy duty (like railway buffer). Custom made springs are also frequently utilized to better suite the intended requirement.

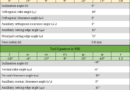

Helical spring is made by winding a small diameter coil or wire in the form of helix. Gap between two adjacent coils of the helix can be varied according to the desired property. Based on this gap, helical springs can be classified as close coiled helical spring and open coiled helical spring. While making a helical spring, if coil is wound tightly providing no visible gap between two adjacent coils, then the same is called close coiled spring or extension spring. On the other hand, when sufficient gap is provided between two adjacent coils, then the same is called open coiled spring or compression spring. Therefore, both are helical springs, but with varying space between two adjacent coils. Various differences between close coiled and open coiled helical springs are given below in table format.

Table: Differences between close coiled and open coiled helical spring

| Close Coiled Spring | Open Coiled Spring |

|---|---|

| Wire of the close coiled helical spring is wound tightly providing no gap between two adjacent coils of the spring. | Wire of the open coiled helical spring is wound not so tightly and thus sufficient space or gap exists between two adjacent coils. |

| Helix angle of this spring is usually 10° or below that. | Helix angle of this spring is more than 10°. |

| Pitch of spring wire is smaller due to small helix angle. | Pitch of spring wire is comparatively larger as a result of larger helix angle. |

| Close coiled springs cannot undergo axial compression. It is designed to resist stretching and twisting. | Open coiled springs are designed to undergo extension and compression; and deflect its length accordingly under the action of axial load. |

This type of spring is commonly used in heavy duty applications such as:

|

This type of spring is commonly used in low duty applications such as:

|

Winding of coil: Every helical spring is made of wire or coil having constant cross-section and is wound in the form of helix. Gap between two adjacent coils of the helix can be altered to obtain desired effect. Length of the spring and its capability to deflect under external loading greatly rely on this gap. When the coils are wound tightly in such a way that there exist no noticeable gap between two adjacent coils then the corresponding spring is termed as close coiled helical spring. On the contrary, when sufficient gap is provided between two adjacent coils then corresponding spring is termed as open coiled helical spring.

Helix angle and pitch: Helix angle of the spring is usually used to differentiate the two. Helix angle of the close coiled helical spring is limited to 10° maximum. Apparently, the plane containing each coil of such spring is perpendicular to the spring axis. Moreover, small helix angle also reflects smaller pitch. Pitch of a helical spring is defined as the axial distance between two similar points on the adjacent coils. On the other hand, springs with helix angle larger than 10° is called open coiled helical spring. Consequently, such springs have longer pitch.

Resisting deflection: Solid length indicates length of the spring along its longitudinal axis when the spring is compressed in such a way that there exist no noticeable gap between two adjacent coils. Whereas, original length of the spring in absence of external load is called free length. In case of close coiled helical spring, the solid length and free length are almost same. Thus no further compression is possible; however, they can elongate under tensile loading. In fact, these coils are designed to resist stretching and twisting. Helical torsion spring, which is used to transmit torque, is one type of close coiled spring. On the contrary, open coiled springs can undergo significant elastic elongation as well as compression under the action of external axial loading. However, they cannot resist twisting.

Applications: A close coil spring is suitable if it experiences either axial tensile loading or torsion during its service life. Most helical torsion springs are close coiled. Typical applications of such springs include garage doors, trampolines, vice-grip pliers, self-closing door hinges, bike or cycle stand spring, etc. On the other hand, open coil spring is suitable if it experiences axial compressive or tensile forces or both in certain cases. Every vibration absorber (including vehicle buffer and damping equipment) utilizes this type of spring. Such springs are also used in automobile brakes, clutches, valves, etc. Another well-known example include spring-operated ball point pen.

Scientific comparison among close coiled helical spring and open coiled helical spring is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Design of Machine Elements by V. B. Bhandari (Fourth edition; McGraw Hill Education).

- Machine Design by R. L. Norton (Fifth edition; Pearson Education).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand; 2014).