Spring is a flexible mechanical element that can undergo significant amount of elastic deformation under the action of external loading. While experiencing elastic deflection, spring can absorb mechanical energy and store it within itself, which is subsequently released in a controlled way when it regains original shape and size. It has wide area of application starting from low-duty requirements (such as spring-operated ball point pen, self-closing door hinge, bike or cycle stand spring, spring-loaded toys and watches, etc.) to heavy-duty requirements (such as cam-follower, brake, clutch, vehicle suspension, railway buffer, vibration damper, etc.).

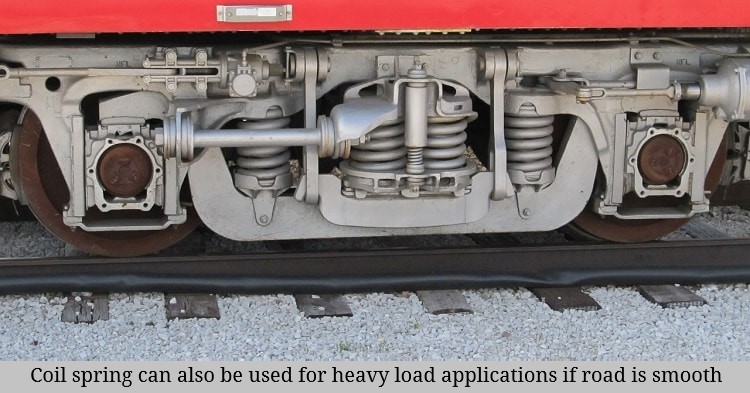

There are different types of springs made of different materials to fulfil varying requirements. Helical spring, leaf spring, spiral spring, Belleville spring, volute spring, disk spring, etc. are notable one. Among them, helical spring has wide range of applications. Specialized springs are also frequently used to suite the intended purpose. In its service life, a spring may experience axial loading (tensile or compressive), torsion, bending, or a mixed type of loading. A particular type of spring is selected on the basis of certain parameters such as intended purpose, nature of force, durability requirement, available apace, working condition, etc. Both coil spring and leaf spring are suitable for vehicle suspension system and railway buffer system; however, no one can fulfil each and every requirement for such purpose.

A coil spring, also called helical spring, consists of a small diameter wire bent in the form of helix. Apart from material, wire diameter, helix angle, gap between two adjacent coils of the helix, and also end type of the spring can vary one spring to another. Such springs are simple in construction, have light weight, and requires minimum space for installation. When installed in vehicle, they offer jerk-free motion but they cannot withstand under heavy load. On the other hand, leaf spring (also called laminated spring) consists of a number of flat semi-elliptical plates of varying length clamped together. They can endure heavy load but show poor vibration damping capability. Various differences between coil spring and leaf spring with respect to vehicle suspension are given below in table format.

Table: Differences between coil spring and leaf spring

| Coil Spring | Leaf Spring |

|---|---|

| Coil spring is made by winding a constant diameter wire in the form of helix. | Leaf spring is made by clamping a series of flat plates of varying length one above another. |

| Although the coil is wound in helical path, basic shape of helical spring is cylindrical (hollow). | Basic shape of leaf spring is semi-elliptic. |

| Coil spring offers small amount of flexibility in transverse direction. | Leaf spring does not offer flexibility in transverse direction. |

| Load bearing capacity of this type of spring is comparatively lower. | Load bearing capacity of this type of spring is much higher. |

| Coil spring tends to absorb shocks and vibrations and thus provide a comfortable ride. | Leaf spring tends to lift of the vehicle body when it experiences bumps. So it cannot provide comfortable ride. |

| Helical springs are light weight and cheaper. | Generally leaf springs are heavy and costly. |

How the springs are made? A leaf spring consists of multiple flat plates of varying length clamped or laminated together using rebound clips and bolts. Each flat plate is termed as leaf. The leaf length gradually decreases from top to bottom. The top most leaf, the longest one, is called master leaf and it is bent at both ends. Each leaf is of semi-elliptic shape and the overall spring also have similar shape. On the contrary, helical spring is made by winding a constant diameter coil or wire in the form of helix. Although the wire remains in the form of helix, overall helical spring occupy a hollow cylindrical shape.

Transverse flexibility: Small amount (usually up to 10°) of deflection of the suspension system in cross or transverse direction is necessary to drive the vehicle in rough roads. Such deflection is also useful while taking sharp turns. Coil spring can provide such flexibility in cross-movement. Thus this type of spring is suitable for such cars which are meant for running in rough, hilly and village road conditions. Leaf spring provides no such cross-deflection of the suspension system.

Load bearing capacity: Leaf spring totally dominates coil spring when load carrying capacity is the matter of interest. Heavy industrial trucks are fitted with leaf spring. Moreover, speed barkers (especially steep bumps) of the road exert enormous reactive force when vehicles, even in slow speed, run over it. Leaf spring can comfortably endure such jerk without much problem. Coil spring may fail by buckling if load exceeds certain limit.

Comfortable journey: Coil spring offers a comfortable and jerk free journey even when the vehicle is driving on in rough road. Thus it is preferred for passenger vehicles. However, in such road, leaf spring tends to lift up the vehicle body, especially when the vehicle is unloaded. So it is preferred in heavy trucks where comfortability is not prime factor.

Weight and cost: Leaf spring is heavy and costly, although it is simple in construction and installation. It also requires larger space for installation. On the other hand, coil spring is of light weight and in majority of the cases it is cheaper.

Scientific comparison among coil spring and leaf spring in terms of vehicle suspension is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Design of Machine Elements by V. B. Bhandari (Fourth edition; McGraw Hill Education).

- What’s the Difference Between a Leaf Spring and a Coil Spring? By generalspringkc.com.