A prime mover is used to generate mechanical energy by converting from other form of energy. For example, electric motor converts electrical energy to mechanical energy and delivers the same in the form of shaft rotation. Similarly, hydraulic turbine, steam turbine, wind mill, etc. can also act as prime mover. Mechanical drives are used to transmit motion, torque and power from such prime movers (driver shaft) to machine parts (driven shaft). Apart from transmission, they can also change the direction of rotation and alter the speed according to the requirement in the machine unit. There are four mechanical drives, namely gear drive, belt drive, chain drive, and rope drive. Such drives also take help of other power transmission elements (like shaft, key, coupling, brake, clutch, pulley, sprocket, etc.) for efficient and uninterrupted power transmission.

Each of the four mechanical drives has respective benefits and limitations; and thus are suitable for specific purposes. These four drives can be classified in several ways on various basis. One such basis of classification is means of power transmission. In all such drives where power is transmitted by means of friction force between two mating parts are called friction drive (for example, belt drive). When power is transmitted by means of engagement, then that type of drive is termed as engagement drive (for example, gear drive and chain drive). Another factor of classifying mechanical drives is presence of flexible elements. All such drives where an intermediate flexible linkage exists between driver and driven shafts are called flexible drive; whereas, if no such intermediate linkage exist then it is grouped as rigid drive. Belt drive and chain drive both come under flexible drives; whereas gear drive is one rigid drive.

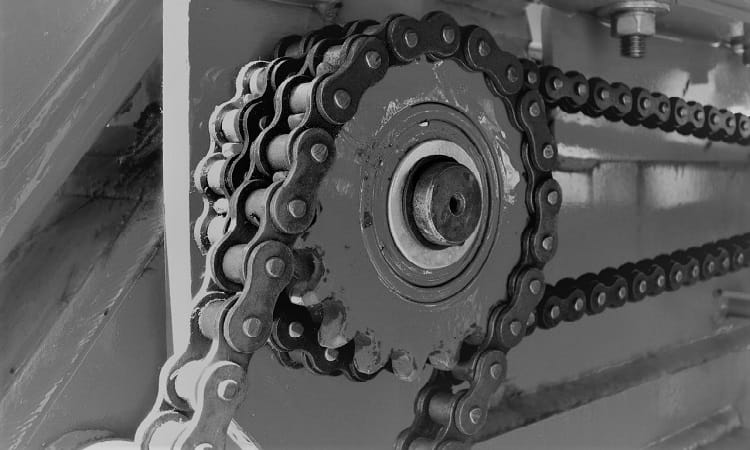

Belt drive is one flexible friction drive, which transmits power and motion from driver to driven shaft by means of friction force in between pulley and belt. It is suitable for medium to long distance power transmission. However, its capacity is limited to frictional force between belt and pulley. Thus it is not suitable for heavy power transmission requirements. On the other hand, chain drive is one flexible engagement drive where power is transmitted by means of successive engagement and disengagement of chain with sprocket. While belt drive is prone to slip, chain drive is free from it; however, it may not necessarily provide constant velocity ratio. Various differences between belt drive and chain drive are given below in table format.

Table: Difference between belt drive and chain drive

| Belt Drive | Chain Drive |

|---|---|

| Belt drive is one friction drive. | Chain drive is one engagement drive. |

| It is one non-positive drive because of frequent slip and creep. | Chain drive tends to offer a positive drive as it is free from slip. |

| Belt drive is preferred for medium to large centre distance. | Chain drive is preferred for small to medium centre distance. |

| Only one face of the belt can be utilized for transmitting motion and power. | Both faces of the chain can be simultaneously utilized for transmitting motion and power. |

| Due to friction loss, efficiency of belt drive is comparatively low (92 – 96%). | Negligible friction loss results higher efficiency in chain drive (95 – 98%). |

| Workroom temperature influences performance of belt drive. | Chain drive is usually not affected by workroom temperature. |

| Although belt drive is commonly used for parallel shafts, a quarter-turn belt can be employed for perpendicular shafts. | Chain drive can transmit power between parallel shafts only. |

| Small angular and locational misalignment posses no problem in belt drive performance. | Chain tends to leave the sprocket if alignment is not perfect. |

| To tight the belt with pulleys, an initial tension is desired, which increases load on shafts. | Additional load on shaft is eliminated in chain drive as initial tightening is not desired. |

| Belt drive requires minimum lubrication. | Chain drive requires proper and regular lubrication for longer life. |

Friction and engagement drive: In friction drives, power and motion transmission occur by means of friction between two parts. Belt drive is one friction drive as frictional force between pulley and belt acts as the means for power transmission. Similarly rope drive also one friction drive. On the other hand, when power and motion transmission occur due to successive engagement and disengagement of toothed parts, it is termed as engagement drive. Here friction force plays no direct role in power transmission. For example, in chain drive, power is transferred by means of mating of toothed sprocket with corresponding chain. Similarly, gear drive is also one engagement drive.

Slip and positive drive: A positive drive is one that offers constant velocity ratio during the operation. Various phenomena such as slip, creep, polygonal effect, etc. tend to alter rotational speed and thereby hamper velocity ratio. A constant velocity ratio is highly desired in various operations such as thread cutting in lathe. Gear drive is only mechanical drive that can offer true positive drive. Belt drive is prone to slip and cannot provide constant velocity ratio. Although V-belt and ribbed belt tend to minimize slip rate, but creep can also hamper velocity ratio. On the other hand, chain drive is free from slip; however, polygonal effect can change velocity ratio undesirably.

Preferred shaft distance: Basic purpose of mechanical drives is to transmit motion and power from driver shaft (such as prime mover) to driven shaft (such as machinery). Distance between driver and driven shaft may vary based on many factors including floor layout. Gear drive is preferred for small distance power transmission. Flat belt drive is suitable for medium to large distance (3 – 15m); however, V-belt can be used for small distance also (typically up to 1m). If the shaft distance is more then belt will tend to whip (vibrate in between two pulleys). Slack side of the belt can also bend down. Thus additional supports may be required. On the other hand, chain drive is preferred for small to medium distance power transmission. Chain is usually heavy as compared to belt and thus it can substantially increase system weight if it is used for long distance. Supporting sprockets are also desired when chain length is more.

Feasible faces: In case of flat belt, only inside portion of the belt comes in contact with the pulley. Even in cross-belt arrangement, belt is bent in two different planes to make sure only inside portion comes in contact with pulley. In V-belt, only two inclined side faces come in contact with the corresponding pulley. These contact faces cannot be altered; for example, outside portion of the flat belt cannot be utilized for power transmission. However, chain drive provides the possibility of using both sides (inside and outside) without any problem. Even both sides can be used simultaneously, when multiple (at least 3) shafts are required to drive by one driver shaft.

Efficiency: Being a friction drive, power loss occurs in belt drive due to friction. This reduces efficiency of the drive. In single stage, belt drive can offer an efficiency in the range of 92 – 96%, mainly depending on frictional characteristic of mating surfaces, initial tension, type of belt, wrap angle, slip and creep. A chain drive can provide better efficiency as frictional loss is negligible. Properly lubricating new chain can typically provide 95 – 98% efficiency.

Workroom temperature: Most of the engineering materials exhibit changes in dimension with temperature; however, the degree of change depends on coefficient of thermal expansion of the concerned material. Belt is usually made of rubber, fabric rubber, ply leather, or synthetic materials. Being a non-metallic material, belt undergoes significant changes in dimension with small variation in atmospheric temperature. Even humidity can affect performance. When temperature increases, belt length also increase and this results in more slip, loss of power, unstable velocity and degraded efficiency. With reduction in atmosphere temperature, belt length decreases, which results in higher load on the bearings (it mounts the shafts). Small variation in workroom temperature poses no detectable problem in chain drive. Since chain is lubricated properly, so impact of humidity is also negligible.

Shaft orientation and misalignment: A suitable mechanical drive is required to select based on the orientation of the driver and driven shafts. Belt and chain drives can transmit power between parallel shafts only. Although quarter-turn belt can be employed for perpendicular non-intersecting shafts, it is not popular because of many restrictions and poor performance compared to bevel or worm gear. A small angular or locational misalignment in fixing the pulleys with corresponding shaft does not pose any problem in power transmission. On the other hand, chain drive cannot be used for non-parallel shafts. It always requires proper alignment of sprockets, otherwise slots of the chain will not match with the teeth of sprocket and thus chin will tend to jump out of the sprocket.

Initial tension: Belt drive requires an initial tension based on the load required to carry and speed of operation. Frequent adjustment of belt tension is also desired to mitigate the effects of gradual increment in belt length. This initial tension increases load on the bearings. Chain drive, however, does not require such tension to be maintained in chain for power transmission.

Lubrication: Belt drive requires occasional lubrication only. Higher than desired lubrication is detrimental as it undesirably increases slip. Chain drive requires frequent lubrication; however, not full lubrication as it is desired in gear drives. Cost of lubricating oil is another factor to consider in chain drive as compared to belt drive.

Scientific comparison among belt drive and chain drive is presented in this article. The author also suggests you to go through the following references for better understanding of the topic.

- Design of Machine Elements by V. B. Bhandari (Fourth edition; McGraw Hill Education).

- Machine Design by R. L. Norton (Fifth edition; Pearson Education).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand; 2014).